A while ago, one of the feet on my kitchen sink grid broke, so I had to do something about it. At the time, all the shops were in lockdown, and even so, I doubt they would have such a specific item anyways.

What to do? I’m not gonna let the exposed steel of the grid scratch the bottom of the kitchen sink. I don’t think my parents would appreciate that.

Fortunately, I’ve got a 3D printer.

I designed and printed a 3D printed replacement foot, which fit quite nicely. I didn’t round any of the edges but it is still able to serve its purpose. I used black PLA so that it matches. You can’t even tell the difference, even up close.

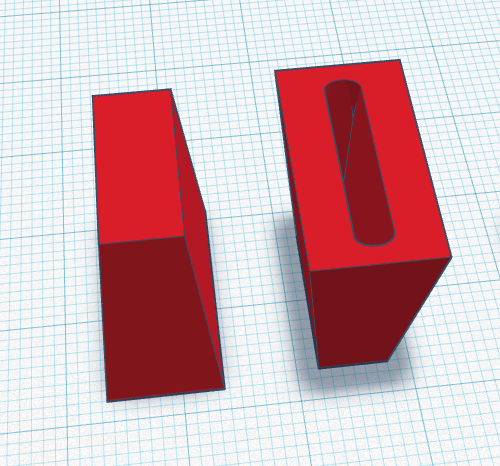

The top and bottom of the foot in Tinkercad, which is what I used to make the model.

The top and bottom of the foot in Tinkercad, which is what I used to make the model.

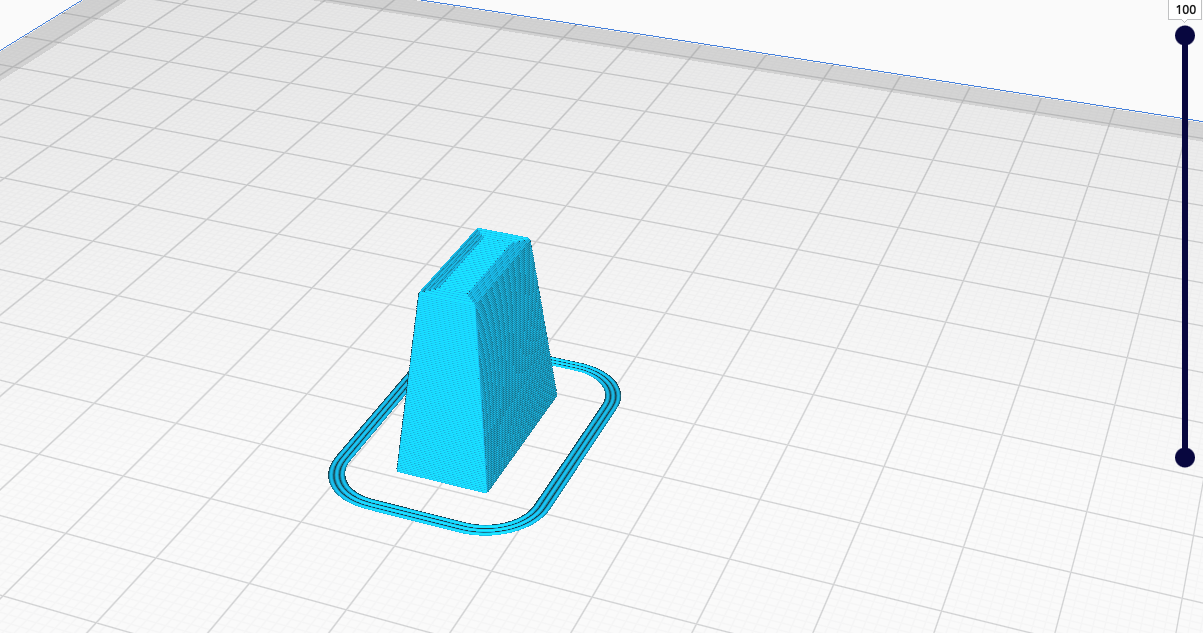

The foot imported in the Ultimaker Cura printing software.

The foot imported in the Ultimaker Cura printing software.

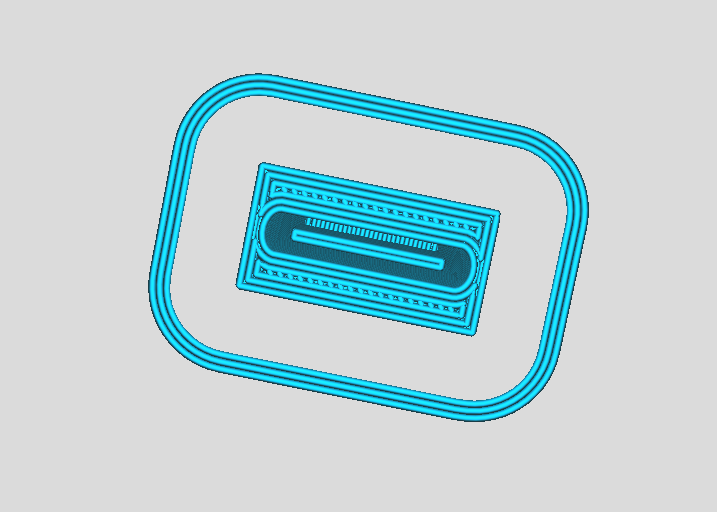

As always, due to the shape, I needed to print supports on the inside to hold up the top.

There needs to be a support printed in the hole. Here, it's basically just a small rectangular block. It can be removed with some pliers.

There needs to be a support printed in the hole. Here, it's basically just a small rectangular block. It can be removed with some pliers.

The supports needed to be removed after printing using a pair of pliers and a razor pen, which is easier than it looks. The print took only 21 minutes which is expected, considering its size.

So all in all, this replacement works great and really shows the usefulness of investing in a 3D printer, provided that you also know how to design your own STL models in a CAD software, which is not that difficult (even without that know-how, you can still download pre-made files off of websites like Thingiverse, although obviously, you’ll need to design your own stuff if they don’t have what you want). I think it would be better if I printed using TPU instead of PLA, so that it is more rubbery and elastic; this would allow it to fit on the foot much easier since it is less rigid, and it would also not scratch the bottom of the sink as much. That being said, PLA has an advantage over ABS, another type of plastic; since ABS is harder, it would cause the foot to scratch the sink’s surface even more. However, ABS also has better flexural strength, which, like TPU, would also make it easier to slip onto the bottom of the grate.

As a bioplastic, PLA may also decompose over time in damp environments (which is why you store your filament in a dry area), but so far, it's holding up. Thanks for reading!